The cost of a breakdown can become enormous compared to the individual price of the keyboard alone.

Analysis and Expertise of flexible keyboards already manufactured in prototype or pre-series versions before launching final production by the chosen subcontractor, in order to :

- Not to tarnish the brand image of the company offering the final device following operating problems

- Not to undermine the quality of the product itself and shorten its lifespan when sold to customers

Finally, to avoid the overall breakdown of a device which may be due to a single malfunctioning key and block it until it is replaced.

For keyboards coming from abroad and particularly from Asia, to be sure of their initial operation, the electrical concordance with its matrix table and compliance with the customer’s request.

The complete electrical test of the ohmic resistance in the loop of each switch, the correct direction of components such as LEDs with ANODE / CATHODE (or other), etc …

Check the concordance of the specifications with the product produced : ADHESIVE – MATERIALS – IK – IP and OTHERS.

Find the origin(s) of a breakdown or defect and guide the solution paths, for the resolution of the existing problem(s).

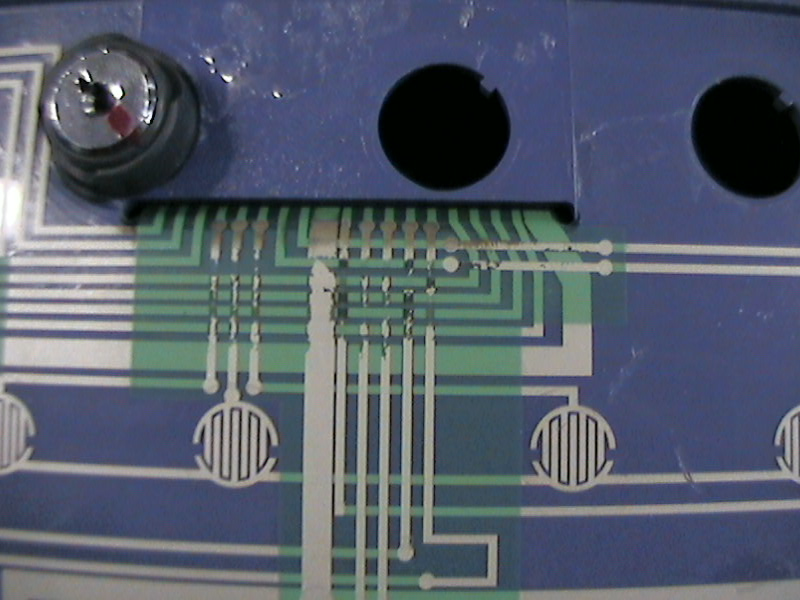

STRONG ELECTROLYSIS EFFECT

ELECTROLYSIS PHENOMENON ON KEYBOARD NOT SUITABLE FOR DAMP LOCATION